View examples of projects undertaken by Cubit Electrical & Mechanical Engineering…

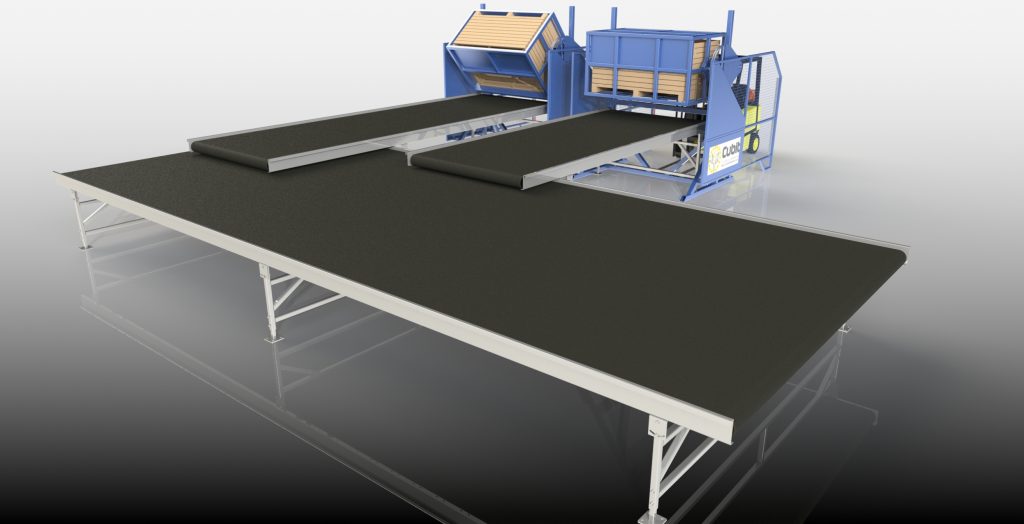

BESPOKE ROLLER CONVEYOR

Cubit Electrical & Mechanical Engineering designed and manufactured this bespoke Roller Conveyor for one of the largest meat processors in the world, Dalehead Foods (part of Pilgrims Pride Ltd – Britain’s biggest higher welfare pig farmer and producer of quality pork products).

FABRICATION OF HOPPER TUNDISH

Here’s another impressive example of fabrication by the professional fabricators at Cubit Electrical & Mechanical Engineering.

This unique stainless steel hopper tundish for a vertical form machine was ordered on a Tuesday. After being processed, drawn, laser-cut, pressed, welded and then cleaned, the finished item was hand-delivered to our client on Wednesday morning!

HORTICULTURALIST EQUIPMENT MODIFICATIONS

These pictures show horticulturalist equipment (a tulip planting line belonging to a premier tulip supplier) undergoing modifications in the Cubit Electrical & Mechanical Engineering workshops. We made significant improvements to this equipment to increase throughput for our client.

Before investing in replacement equipment, speak to Cubit regarding refurbishment and modifications to improve efficiency.

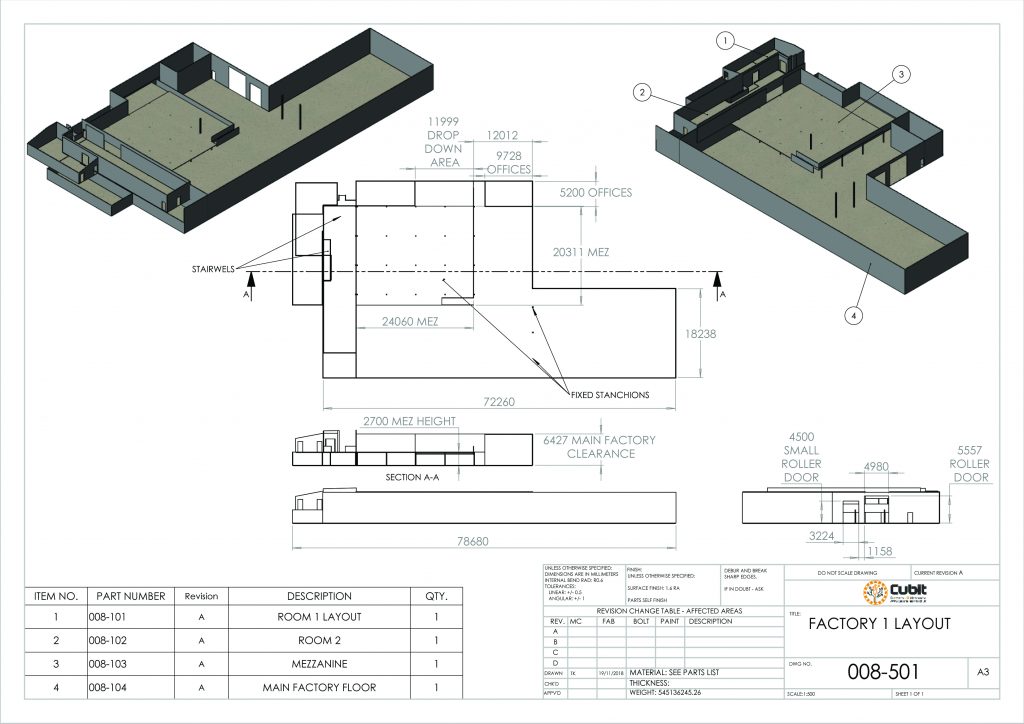

MEZZANINE FLOOR

Installing a mezzanine floor is a convenient way to expand floor space within existing premises by adding another floor level.

Cubit Electrical & Mechanical Engineering designed this large mezzanine floor for a logistics and co-packing facility in order to increase their capacity.

We use award-winning Solidworks CAD software which also allows us to plan the efficient relocating and modifying of existing equipment to truly maximise the space available.

ELEVATOR CONVEYORS

Here at Cubit Electrical & Mechanical Engineering we design, build, modify and repair Elevator Conveyors. We manufacture and install entire conveyor systems which are tailored to the precise requirements of each client. We have vast experience of installing and maintaining conveyor systems in a range of environments (including farming and food processing).

This particular Elevator was manufactured at our extensive workshop near Spalding in Lincolnshire and installed on site by our skilled mobile engineering fitters.

CO-PACKING CONCEPT LINES

Cubit Electrical & Mechanical Engineering used award-winning Solidworks CAD software to produce several concept packing lines for a new co-packing operation. We were selected to provide these bespoke models with options and recommendations to assist with tendering for an international distribution company.

Cubit have expertise in designing and manufacturing bespoke packing lines of all types.

SWEET POTATO CONVEYOR

This bespoke conveyor was designed, built and installed by Cubit Electrical & Mechanical Engineering for hand-sorting Sweet Potatoes by our client ‘Mason Brothers’.

If you require conveyors for your business, please contact Cubit Engineering to discuss your requirements in detail.

BESPOKE STRUCTURAL STEELWORK

Cubit Electrical & Mechanical Engineering fabricate bespoke Structural Steelwork for clients in the construction industry. Steel has traditionally been used within industrial buildings but it is increasingly used to form a strong skeleton for modern residential dwellings too.

The Cubit workshop is ideally equipped for our fabricators to reshape structural steel via cutting, bending, and assembling in order to create precision sections including beams, channels, angles, girders, columns, plates and hollow steel tubes.

3D PRINT REPAIR

This broken link from a white plastic multi flex chain belonged to our clients conveyor system. The lead time for delivery of a replacement component was 5-7 days, so when the breakdown was reported to Cubit Electrical & Mechanical Engineering we moved swiftly to resolve the issue.

Our staff collected the broken part and we set to work drawing a detailed replacement component which was produced using our in-house 3D printing facilities. Just a few hours later the new black component was delivered and installed, preventing downtime for our delighted client.

NEW BANDSAW!

Meet our robust new industrial Bandsaw for fabricating all things large!

We reckon our large capacity UZMA Semi-Automatic Double Mitre Bandsaw is one of the biggest saws in the area, which is proving to be a great addition to the Cubit Electrical & Mechanical Engineering workshop.

It weighs 1.5 tonnes and has a 3.5kw motor, making it ideal for cutting of solid metals. The versatile Mitre Head swivels 60 degrees in both directions for accurately cutting profiles.

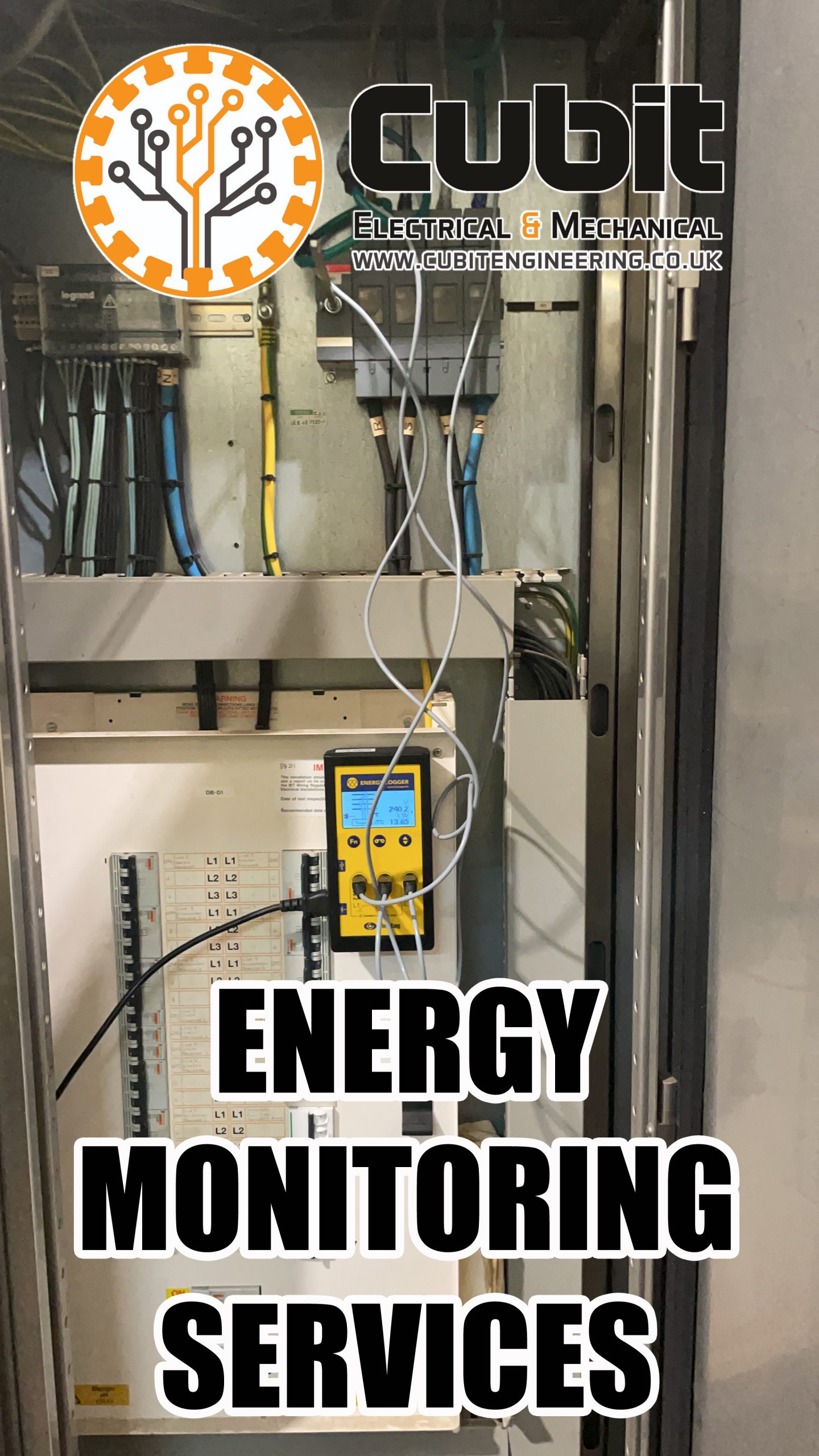

ENERGY MONITORING SERVICES

Cubit Electrical & Mechanical Engineering offer energy monitoring for equipment and production lines in order to diagnose faults or streamline operations to improve efficiency.

We can provide critical data to help control your electricity consumption and reduce energy costs.

Contact Us for details.

INDUSTRIAL WASHING EQUIPMENT

Cubit Electrical & Mechanical Engineering provide washroom equipment to help achieve high standards of hygiene, particularly for the food processing industry.

This image shows two hygienic ‘Welly Wash’ industrial washing machines which Cubit installed to prevent contamination from boots in the workplace.

STAINLESS STEEL FABRICATION

These pictures show innovative exit chutes which we created for a Dolav Wash and a Tray Wash, plus two bespoke Tray Holders at an abattoir facility.

The Stainless Steel was cut, pressed and welded by professional fabricators at our workshop. We provided evening delivery and installation of these improvements to avoid interruption to our clients busy production schedule.

MDPE ELECTROFUSION WELDING

Cubit Electrical & Mechanical Engineering can provide specialist MDPE Electrofusion welding of plastic pipes for industrial applications.

MDPE Electrofusion fittings are designed with built-in electric heating elements which are heated in order to weld pipe systems together. The pipes to be joined are cleaned, inserted into the electrofusion fitting and a voltage applied for a fixed time depending on the size of the pipe and fitting being installed. The MDPE electrofusion process produces very strong joints which can last for upwards of 50 years.

Chalk Weighing System

Cubit Electrical & Mechanical Engineering manufactured this customised weighing system for a quarry operator. The purpose-made load cell and precision weighing system are used to weigh 25kg bulk sacks of chalk.

This robust weighing system is designed to operate accurately in a harsh and dusty environment. All bespoke components were machined at our workshop prior to delivery and installation. The new weighing system has modernised our clients weighing process to an improved serviceable standard.

Expanded Premises (May 2021)

Here at Cubit Electrical & Mechanical Engineering we have extended our premises in South Lincolnshire by adding an extra 6,000 sq ft to our existing workshops.

The extension has added improved office facilities, increased on-site storage and allows us to accommodate additional equipment as we continue to expand our engineering services on behalf of our clients.

Vegetable Wash Pipework

Cubit Electrical & Mechanical Engineering installed this bespoke pipework supplying vegetable handling flumes for our client RBOrganic. The pipework layout was carefully planned to allow machinery cleaning and optimum access.

Our experienced mobile engineers measured, cut and fabricated all of the pipework on-site prior to installation.

New Drains & Pipework

Cubit Electrical & Mechanical Engineering recently installed drains for a new vegetable washing machine at the RBOrganic Ltd site at Yaxley near Peterborough in Cambridgeshire.

This bespoke 8inch pipework and drain manifold were prefabricated in our South Lincolnshire workshops prior to being installed neatly on-site by our Engineers.

Leek Harvester Repair

The Cubit Electrical & Mechanical Engineering workshops in South Lincolnshire are well equipped to accommodate large scale repairs and fabrication projects for our clients.

Our skilled engineers recently overhauled this lengthy Conveyor which was transported by articulated trailer and handled with precision by forklift. The conveyor belongs to a Self-propelled Leek Harvester owned by a local fresh produce grower.

Greene King Bottle Crowning Machine Repair

Cubit Electrical & Mechanical Engineering were entrusted to repair the bottle crowning machine at Greene King’s main UK bottling plant in Bury St Edmunds.

This state-of-the-art automated machine has individual components which weigh up to 1,000kg each. Precision OEM parts for the worn out 600mm Slew Bearing were couriered from Italy for a 4-man team from Cubit Engineering to strip, replace and reassemble the machine.

Access to the prestigious Greene King site is restricted, and the Cubit team worked around the clock to recommission the machine as soon as possible. Specialist lifting gear was essential, supported by a 2.5 ton low mast forklift which was amazingly delivered to site by Eastern Forklift Trucks Ltd in just 25 minutes!

The intricate repair was successful and Greene King’s crowning machine was able to resume capping around 20,000 bottles per hour!

Weigher Gantry & Frame

Cubit Engineering fabricated this bespoke Weigher Gantry & Frame for trials of new vegan cheese packaging machinery. The gantry was designed using award-winning SolidWorks software and manufactured by our experienced fabricators.

We delivered this equipment to a facility in Ireland for our long-term client PFM Packaging Machinery Ltd.

Cubit Engineering Investment in 2020

Here is the recent arrival of our new Press & Guillotine workshop equipment. Cubit Electrical & Mechanical Engineering have made significant investments and improvements during 2020 as we continue to expand:

- 120 Tonne 4 Metre Press

- 3 Metre 6mm Guillotine (with several top & bottom tools)

- 2 additional new vans

- Solidworks 2020 software

- Latest technology equipment for electro cleaning & etching of stainless steel

- New site tools including portable pipe REMS cutters & large portable Bandsaw for site work

- Electro fusion pipe welder 20mm MDPE – 600mm

- Latest Geberit Mapress tool 15mm-63mm

- 2 new portable TIG welders

- Machine lifting/moving/installation equipment that includes skates, chains, jibs & straps

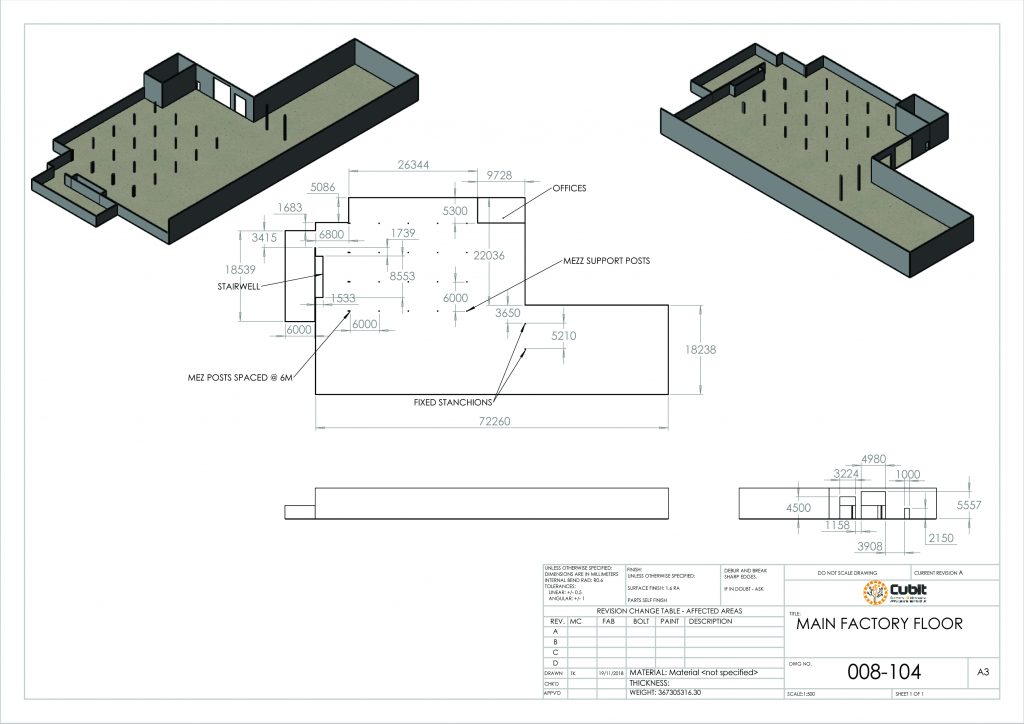

RBOrganics Ltd Crown Roller Grader Repair

Cubit Electrical & Mechanical Engineering’s long standing client RBOrganic Ltd use a giant Crown Roller Grader machine to produce uniform packed organic carrots for consumers.

In March this year a breakdown caused the colossal chains on the Grader to snap. Internal parts, rollers and bearings were also damaged.

A service to this machine would normally take one whole week for 2 engineers, however the team from Cubit Engineering managed to source all materials, fabricate and build parts then fully refurbish and repair/rebuild the machine in just 30 hours!

Planned Factory Move (Ingredients Factory)

Cubit Electrical & Mechanical Engineering assisted our client by carrying out the planned move and time-sensitive recommissioning of this crucial equipment at their ingredients factory. These adaptations were completed safely and on time by our engineers, with minimal disruption to output.

The pandemic lockdown has been challenging for the whole food production industry. Cubit Engineering are proud to have fully supported our clients throughout this period, including adaptations, screens and barriers to make workplaces Covid-19 compliant.

For more details see www.cubitengineering.co.uk/covid-19

Cutting Machine Blade Carrier

A long standing customer recently asked Cubit Electrical & Mechanical Engineering to design a bespoke blade carrier for their FAM precision cutting machine, and here is the finished article just 24 hours later!

This blade carrier will enable them to safely maintain their very expensive blades, avoiding costly damages. This is another example of rapid problem-solving, design and fabrication services by Cubit Engineering.

Cooking Vessel Installation

Cubit Electrical & Mechanical Engineering are proud work with the manufacturers of many well-known food brands that appear on our supermarket shelves. We recently assisted with the installation of these new cooking vessels for a UK-leading Hot Fill Sauce company. Expert engineers from Cubit provided fabrication, plus the installation of water, electricity and air supplies.

Chute Modification & Fabrication

Here is Cubit Engineering’s skilled Fabricator Andy welding some bespoke metal chutes that were re-designed for a client. Crucially this adaptation allowed existing factory machinery to accommodate a different style of product.

This was a typical time-sensitive task that required a fast turnaround to minimise disruption. Andy made a quality job as usual, and the parts were delivered back to the client with time to spare.

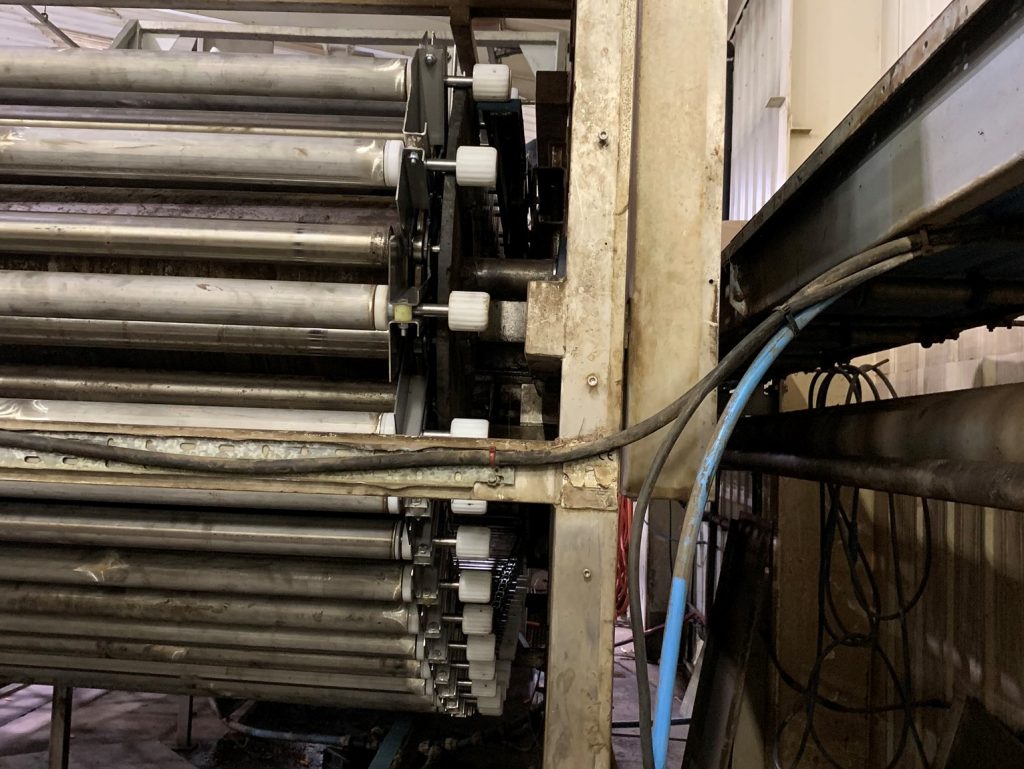

Automated Box Tipper

These are Cubit Electrical & Mechanical Engineering computer drawings of a ‘Box Tipper’ machine produced for one of our clients. This bespoke design includes the option of manual output or fully automated output.

This design illustrates how Cubit Engineering can streamline and improve processes which have previously been laborious or time-consuming. Following initial consultation, our engineers provide design, fabrication and installation, plus maintenance services.

Farm Conveyor Repair

When a nearby farmer contacted us about this severely damaged conveyor, many would have assumed that it was beyond repair. Here at Cubit Electrical & Mechanical Engineering we were confident that it could be fixed.

Our talented engineers straightened the conveyor chassis and then went on to refurbish the conveyor belt back to its original condition, saving the expense of replacement.

Do your engineers provide this level of support?

Fairfield Fresh Peeling Line

Cubit Electrical & Mechanical Engineering are proud to have assisted with the installation of the Fairfield Fresh peeling line for our long-term clients Mason Bros Cold Storage & Grading Services Ltd.

Fairfield Fresh produce high quality Sweet Potato chips for wholesale using a unique supply chain.

Cubit Engineering were involved from the initial concept, helping to design the entire factory. Then following construction, our expert engineers provided full installation of all equipment to efficiently wash, peel and cut the potatoes before bagging the end product.

Subsequently this facility has obtained AA BRC Accreditation for food storage and distribution.

Are you seeking flexible engineers to support your changing business needs? If so, Cubit Engineering can assist with projects of all sizes. We provide installation and maintenance services, plus 24 hour engineering cover when necessary. See www.cubitengineering.co.uk for more details. Please email info@cubitengineering.co.uk or call our friendly team on 07525 363885 to discuss your requirements.

Stainless Steel Fabrication

Here is a practical example of our bespoke engineering – this made-to-measure stainless steel catch tray with drain was supplied by Cubit Engineering to one of our clients. Following fabrication we provided delivery and installation.

This job demonstrates the excellent workmanship created by our expert fabricator Andy, often working to strict time constraints.

Fabrication is just one aspect of Cubit Electrical & Mechanical Engineering. Our experienced team are based in South Lincolnshire and provide a wide range of engineering services to the farming, fresh produce and food processing sectors.

Harkenn Ltd Baler & Conveyor Repair

Cubit Electrical & Mechanical Engineering’s client Harkenn Ltd Recycling contacted us recently to report a breakdown to their Main Baler. Therefore our expert engineer responded to the call-out, attending promptly to discover a broken drive chain. Our quality repair involved:

• Assessment of the breakdown

• Repairing the broken chain

• Splicing a new section of belt onto the existing elevator

• Replacing some damaged metal side profiles (which our supplier RG Laser cut and pressed for us in just 2 hours!)

Because of superb support from Cubit staff and suppliers, downtime was minimised.